Step into our workshop of possibilities, where dreams take shape. We leverage the prowess of SolidWorks 3D design modeling, AutoCAD, and 3D scanning technologies to sculpt your visions into reality. Your ideas become tangible, meticulously crafted with the precision of digital artistry.

Five Laser Cut Metal Technology Pvt Limited

Ready to redefine what's possible in heavy engineering? Dive into the possibilities with 5LC. Your journey towards unparalleled solutions starts here.

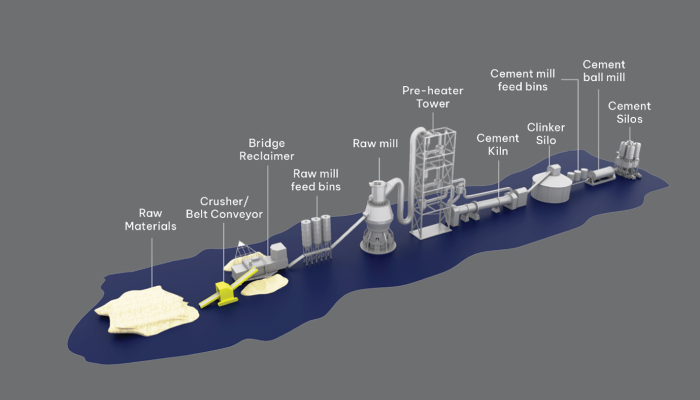

Specifically related to industrial applications, possibly in the context of cement or coal mills, thermal power plants, and other heavy machinery. Here's a breakdown of each point

Where Innovation Meets Affordability in Wear Solutions.

Wear Solutions Crafted for a Cost-Effective Tomorrow.

Redefining Wear Solutions with a Focus on Lifecycle Savings.

Elevating Efficiency, Lowering Costs with Innovative Solutions.

Innovation at the Core, Lifecycle Costs at the Forefront.